Manufacturing

Making full use of various welding and spraying technologies as a pioneer of hardfacing, performing the overlay welding, spraying and machining technologies inherited for many years, we are manufacturing and repairing parts used in various key industries in Japan and overseas.

read moreEngineering

We provide technical support for applications requiring wear and corrosion resistance, consultation on operation cost reduction, and maintenance services based on our extensive experience.

read moreTrading

With technology and knowledge built over many years, we aim to be a company that can provide a variety of proposals by providing the latest information and products in Japan and overseas using a wide network of the world.

read moreApplcation Example by Tokyo Hardfacing, Inc.

Tokyo Hardfacing, Inc. aims to extend the life of the products by using its proprietary hardfacing materials and application

technology as a pioneer of the metal surface hardening against wear and corrosion, which are issues of industrial machinery.

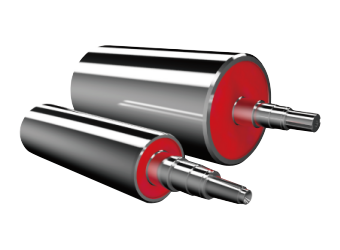

Steel Making

With our proprietary materials and application technology, we improve the wear resistance, corrosion resistance, and heat resistance of the production line at steelworks, and we will extend the life of the product itself and contribute to reducing maintenance costs.

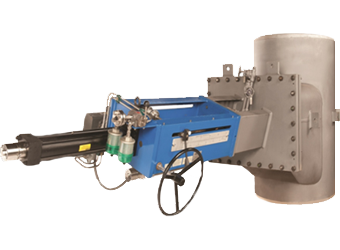

moreOil Refinery

As a countermeasure against corrosion and abrasion of petroleum refining equipment, we apply overlay welding, thermal spraying,and lining construction technology to respond to requests for repairs and modifications to make the equipment more reliable.

moreEngineering Plastics

As a measure to improve the productivity of extruders, in addition to the conventional surface modification treatments such as nitriding and hard chrome plating, we will propose new wear and corrosion resistant solutions according to the application.

moreElectrical Cable

We are producing screws, cylinders, and cross-heads for cable manuracturing extruders. Also, we are offering single unit and/or full line of cable manuracturing equipment made overseas.

more

Thermal Power Plant / Cement Manufacturing

By improving the wear resistance against fly ash etc., the heat and corrosion resistance of the burner opening, and the wear resistance of roller tires and table liners of vertical crushing mills, we propose a reduction in repair costs at thermal power plants and cement manufacturing plants.

moreGeneral Industry

We provide consultation on wear resistance, corrosion resistance and heat resistance in all industrial machinery fields, as well as overlay and thermal spraying on materials and parts supplied by customers.

more

HARD FACING TECHNOLOGYAbout Hardfacing

Hardfacing is a surface hardening method, which is a revolutionary technology that creates a hardened layer with excellent wear resistance on the surface of the main machine parts by various methods and greatly extends the life of the parts.

Specific methods include various welding techniques such as gas welding, TIG welding, PTA welding, and laser welding. As a pioneer of hardfacing, our technology has been well received by customers for half a century.

WHAT’S NEW

- 2019.12.25 The homepage was renewed