We are offering solutions for corrosion and abrasion of petroleum refining equipment.

In particular, for erosion in fluid catalytic cracking units, we will solve the problem by applying the proper material selection, overlay welding, thermal spraying, and lining construction techniques.

We can also design, manufacture, install, repair, and disassemble and maintain special valves such as slide valves.

Products Lineup

-

Vent Adaptor

Adapter for vent hole of twin barrel. Corrosion resistant material is available for this adaptor.

-

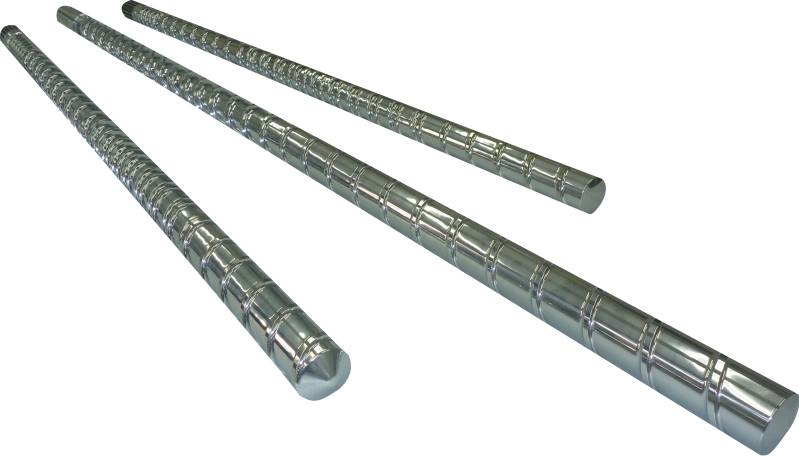

Screw Shaft for Twin Extruder

Normal spline shafts can be manufactured in a short lead time. We also have a lineup of rolling shafts for higher torque.。

-

Single Screw

We will select the material according to the application. We can also repair worn screws

-

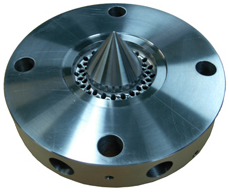

Forward End Flange

It is possible to make drawing by sketching.

-

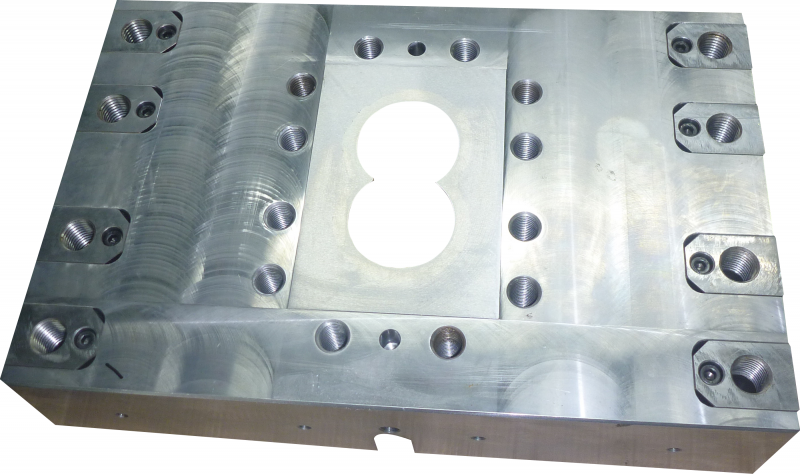

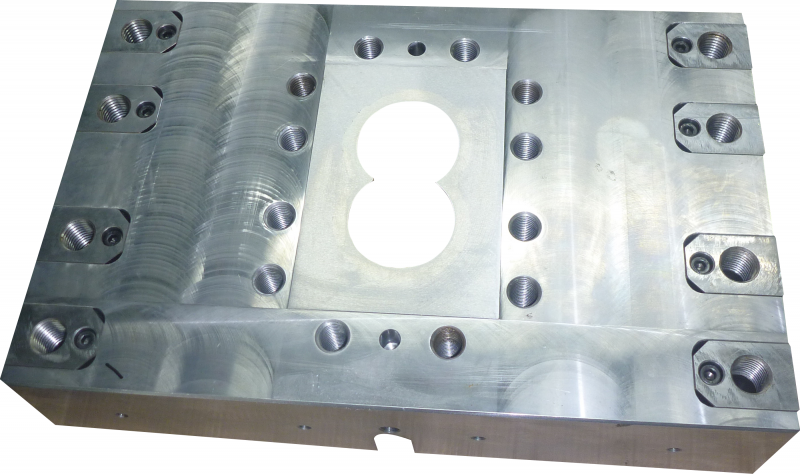

Twin Barrel

Wear resistant / corrosion resistant / liner type is available. We also provide inner diameter wear measurement service.

-

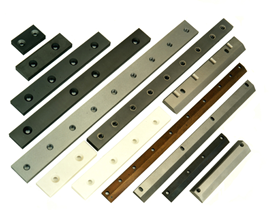

Screw Element for Twin Extruder

We offer screw elements of various materials and shapes in a short lead time in response to higher requirements for engineering plastics.

-

Strand Die

We support various materials, carbide nozzles, and special surface treatments.

-

Underwater Die

We can manufacture pipe dies. Underwater dies can be manufacture with ultra wear-resistant titanium carbide linings

-

Air Wiper

We provide wear-resistant drainers using tungsten carbide.

-

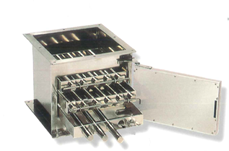

Pelletizer

Achieves high-quality cutting and easy cleaning with a minimum of 0.03 mm of rotor and bed knife gap! Equipped with "digital pellet length control".

-

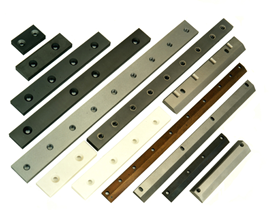

Rotor / Bed Knife / Feed Roll

Wedge-lock type and Bolt-on type rotor with interchangeable carbide blades, Bed knife that can be used at 4 edges, wear resistant and heat resistant resin feed rolls, SUS feed rolls, etc are available.

Introduction of each part

- Vent Adaptor

- Screw Shaft for Twin Extruder

- Single Screw

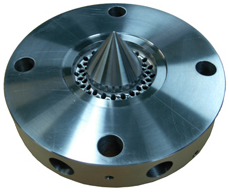

- Forward End Flange

- Twin Barrel

- Screw Element for Twin Extruder

- Strand Die

- Underwater Die

- Air Wiper

- Conveyer

- Magnet Separator

- Cleaning Furnace

- Pelletizer

- Rotor

- Bed Knife

- Feed Roll

Vent Adaptor

Adapter for vent hole of twin barrel. Corrosion resistant material is available for this adaptor.

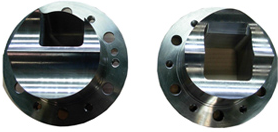

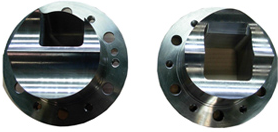

Screw Shaft for Twin Extruder

Normal spline shafts can be manufactured in a short lead time. We also have a lineup of rolling shafts for higher torque.

Single Screw

We will select the material according to the application. We can also repair worn screws.

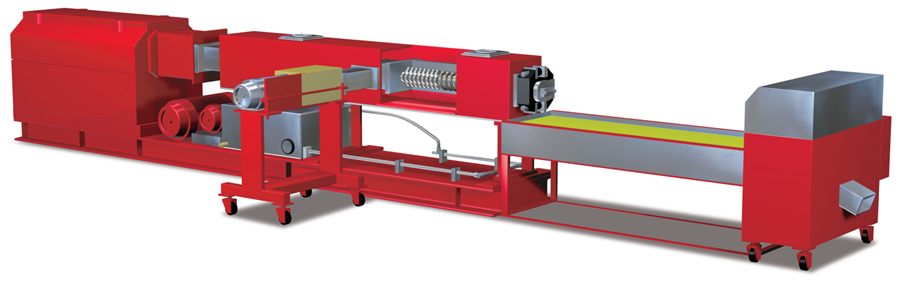

Forward End Flange

It is possible to make drawing by sketching.

Twin Barrel

Wear resistant / corrosion resistant / liner type is available. We also provide inner diameter wear measurement service.

Screw Element for Twin Extruder

We offer screw elements of various materials and shapes in a short lead time in response to higher requirements for engineering plastics.

Strand Die

We support various materials, carbide nozzles, and special surface treatments.

Underwater Die

We can manufacture pipe dies. Underwater dies can be manufacture with ultra wear-resistant titanium carbide linings

Air Wiper

We provide wear-resistant drainers using tungsten carbide.

Conveyer

Auto-strand system synchronized with pelletizer is possible.

Magnet Separator

High magnetic force 15,000 gauss, and heat resistant type is available.

Cleaning Furnace

An environmentally friendly extruder parts cleaning furnace with a secondary combustion furnace.

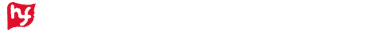

Pelletizer

Achieves high-quality cutting and easy cleaning with a minimum of 0.03 mm of rotor and bed knife gap! Equipped with "digital pellet length control".

Rotor

Bed Knife

Feed Roll

Wedge-lock type and Bolt-on type rotor with interchangeable carbide blades, Bed knife that can be used at 4 edges, wear resistant and heat resistant resin feed rolls, SUS feed rolls,